Arduino has been around for years, and you've probably heard the term. It is an open-source electronics platform that allows developers to connect hardware with software easily. The popularity of Arduino is vast because it offers a simple and accessible user experience. As an iOS developer, I wanted to play around with this platform, so I've built a toy car that can be controlled with a mobile app. Read this article to find out how I did it.

Project outline

There are two key components in this project:

Arduino based toy car.

iOS application for controlling it (connected via Bluetooth Low Energy)

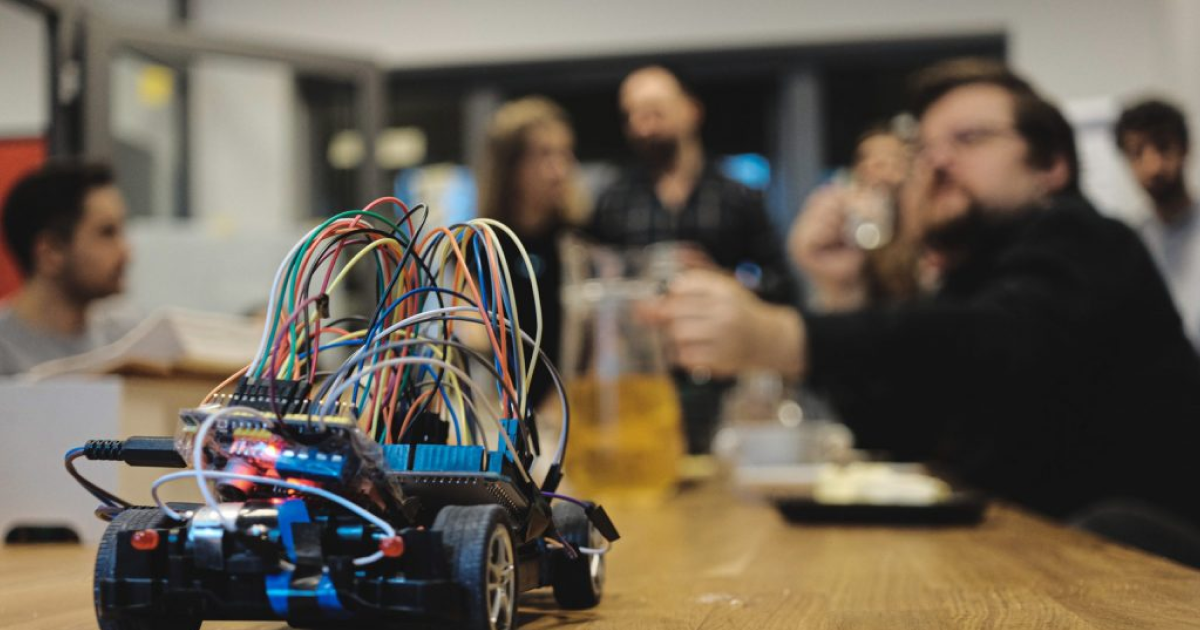

You can see the final result in the picture below. On the left side is an iOS application, on the right side, a toy car.

iOS application

Let’s start with the car controller (iOS application). In this article, I won't go into details about iOS application implementation. I will describe briefly how it works from the user perspective.

The application connects to Arduino using BLE (Bluetooth Low Energy).

After launching it, the device discovery screen is displayed. The application starts searching for Bluetooth devices automatically and displays devices with matching service UUID. User can restart device discovery by pressing the Search button (in case of network errors). The application can automatically connect to the last selected device by checking the Auto-connect checkbox.

The controller screen has four controls:

Drive forward and backward (bottom left corner)

Turn left and right (bottom right corner)

Change gear (buttons 1-5)

Headlights on/off (top right corner)

It shows connection status in the top right corner. By pressing the back button, the application disconnects from the car and navigates back to the device discovery screen.

Toy car

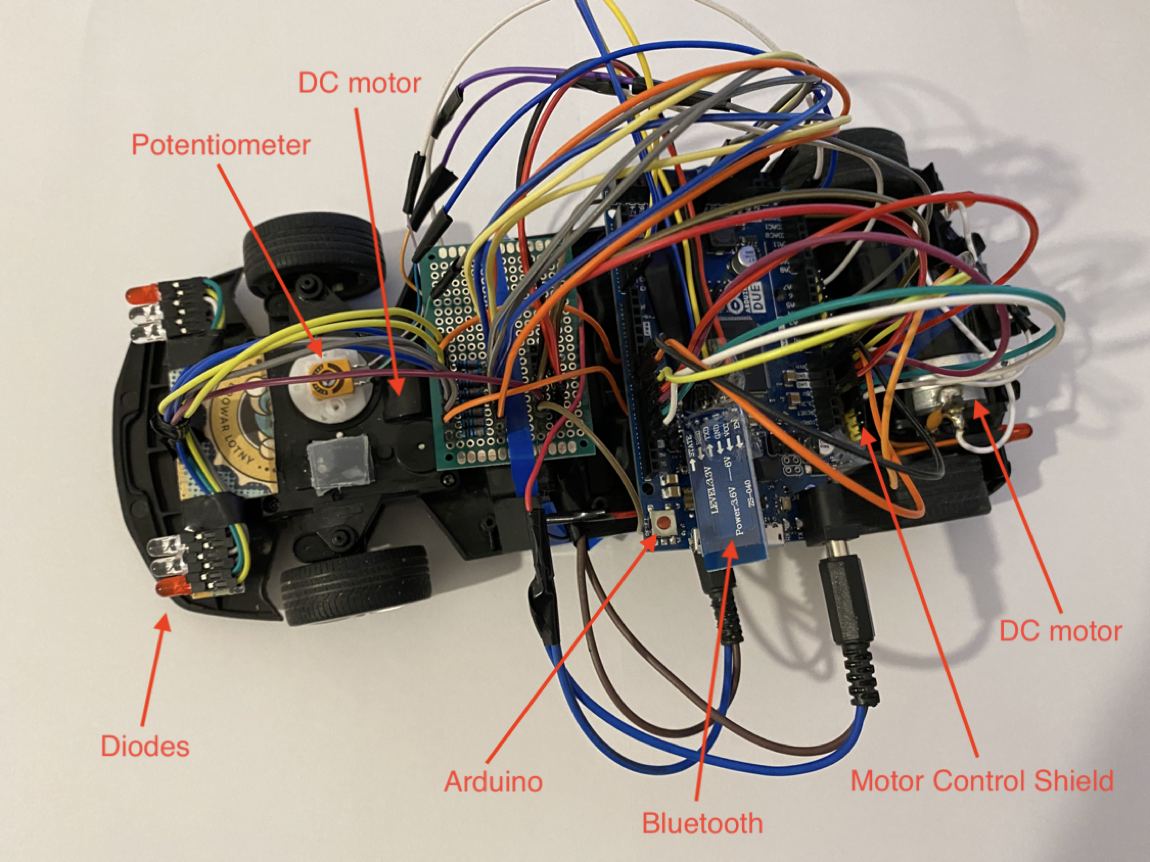

The toy car was built using mechanical parts from an old toy: chassis with wheels and 2 DC motors (one for driving, the other one for turning).

The custom components are Arduino, DC motor controller, Bluetooth, LEDs.

How to build it?

Hardware components

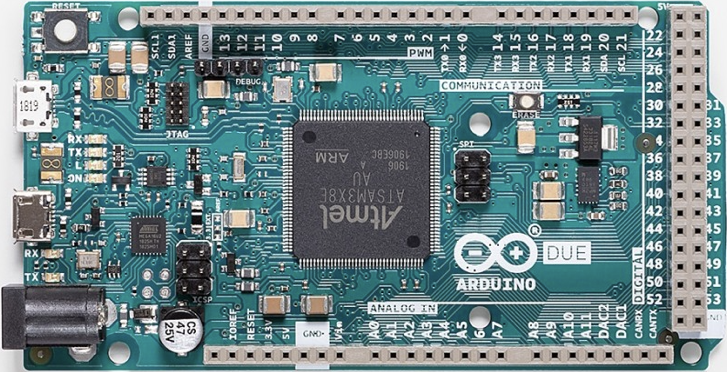

1. Arduino Due

Arduino is an open-source electronics platform based on easy-to-use hardware and software. It can be used for prototyping hardware devices. Implementation is very fast and in a few days, we can have a working device for real-world testing.

It is responsible for controlling hardware components (motors, sensors, LEDs), Bluetooth communication, and handling iOS application commands.

Arduino Due main characteristics:

32-bit ARM core microcontroller (84 MHz clock)

54 digital input/output pins (of which 12 can be used as PWM outputs)

12 analog inputs

4 UARTs (hardware serial ports)

Board runs at 3.3V (unlike most Arduino boards that run at 5V)

Compatible with all Arduino shields that work at 3.3V

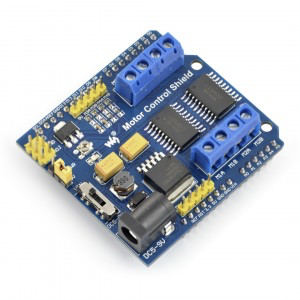

2. Waveshare Motor Control Shield L293D

It is capable of driving 4 DC motors or 2 stepper motors at one time.

When using an external power supply of 9V it allows you to adjust the speed and direction of the motors with current consumption up to 600mA (1.2A peak) and a voltage between 1.25V - 6.45V.

Toy car has two DC motors: the first one is used for driving, the second one for turning.

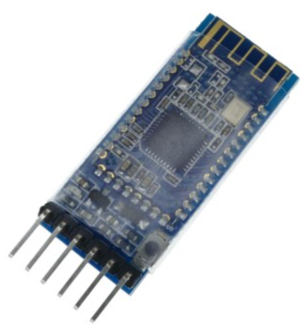

3. Bluetooth module HM-10

HM-10 is a Bluetooth 4.0 module. It works with voltage from 3.3V to 5V, it communicates over a serial UART interface (RX, TX pins). The maximum transmitter power is +6 dBm, the receiver sensitivity is -23 dBm.

4. Two DC motors

DC motor for driving (operation Voltage of 3-6V, free-run current of 200mA).

Mini DC motor for turning (operation Voltage of 3-6V, free-run current of 30mA).

Choose your DC motors depending on the weight of the car.

5. LED lights

4 x red LEDs for turn signals

4 x white LEDs for headlights

6. Other components

8 resistors 220Ω

Potentiometer 10kΩ

6 AA batteries (1.5V)

Wires

Breadboard

Old toy car chassis

How to connect everything?

The photo below shows how components are connected. It doesn’t look pretty, but I assure you that it works 🙂

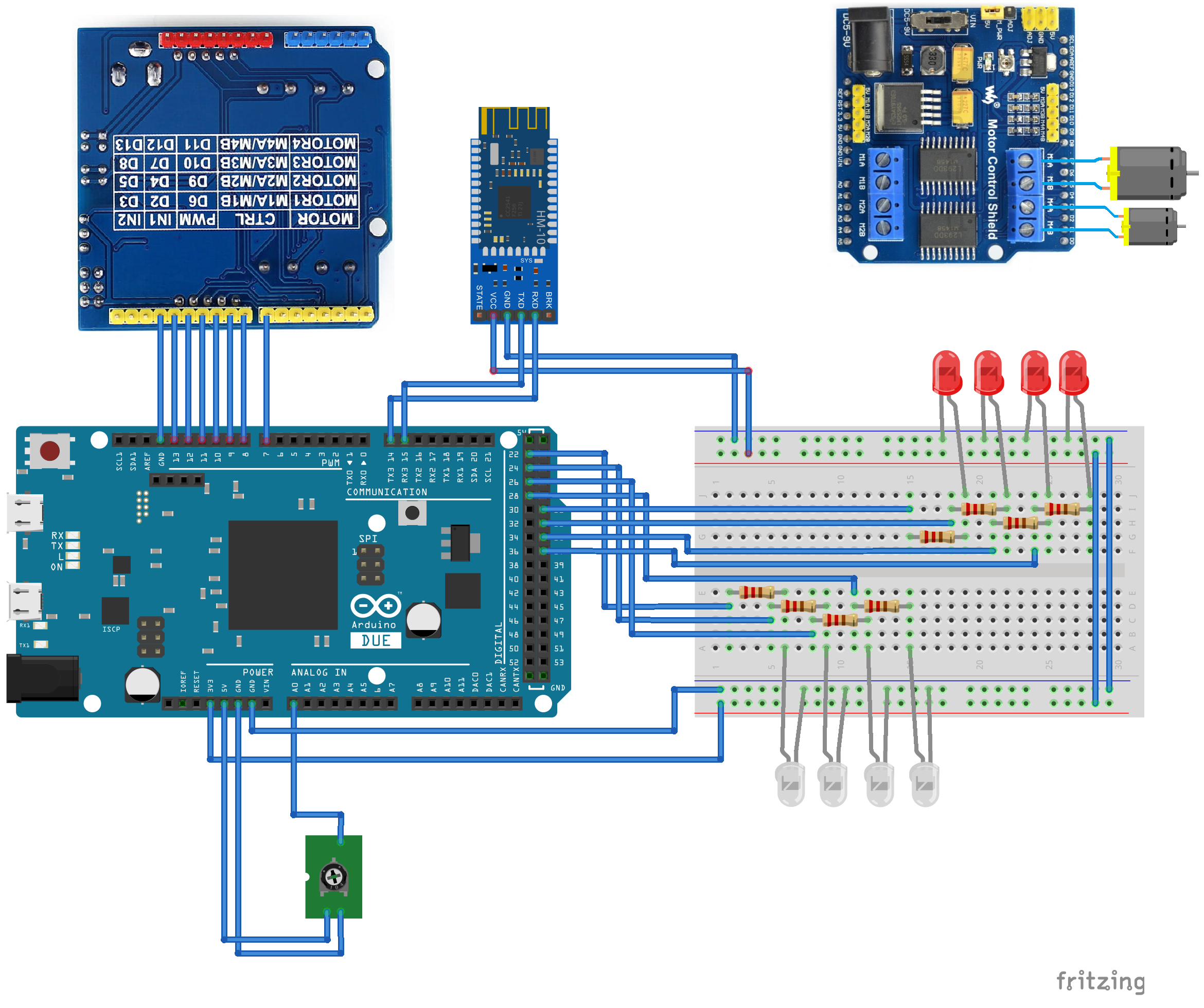

And here is a schematic diagram:

Let’s examine each and every component individually.

1. Bluetooth and the main application loop

One of the biggest advantages of Arduino is that there is a vast set of ready to use components and libraries available. They are very easy to use and don’t require us to write much code. They are named Shields. In this project, I used a Bluetooth Module and a DC Motor Control Shield.

Let’s start with the Bluetooth module first. It communicates with the Arduino board using the Serial port.

Connect Bluetooth module HM-10 pins to Arduino board:

VCC > VCC (5V or 3.3V)

GND > GND

RX > TX3

TX > RX3

Main application setup

Define a helper macro named HC06 that points to a Serial3. configureBle() method starts Bluetooth connection.

1

2

3

4

5

6

#define HC06 Serial3

void configureBle() {

HC06.setTimeout(100);

HC06.begin(9600);

}Define Bluetooth commands for controlling the toy car. iOS application sends commands to the Arduino. Currently, the application supports the following commands: drive, turn on headlights, change gear, turn.

Command length is 3 bytes.

First byte is a command code defined as an enum BleApiCommand.

Second byte is an additional parameter, depending on the command code:

cmdDrive - speed: 0-127 (drive backwards), 127 (stop), 128-255 (drive forward).

cmdHeadlights - 1 (turn headlights on), 0 (turn headlights off).

cmdGear - gear integer between 1-5.

cmdTurn - turn angle: 0-126 (left), 127 (straight), 128-255 (right).

Third byte is a command terminator 0x0f.

1

2

3

4

5

6

7

8

9

const int commandTerminator = 0x0f;

const int commandLength = 3;

enum BleApiCommand {

cmdDrive = 0x23,

cmdHeadlights = 0x24,

cmdGear = 0x25,

cmdTurn = 0x40

};Main application setup method.

1

2

3

4

5

void setup() {

configureLightsPins();

configureMotorPins();

configureBle();

}Main application loop

Main application loop responsibilities:

Read the Bluetooth command. If it is valid, invoke a handleCommand() method. It supports the following commands: drive, turn headlights on and off, change gear, turn.

Turn signals work automatically when car turns, it is handled inside a turnSignalControllerTick() method.

handleTurn() method positions front wheels to the given angle.

stopIfDisconnected() stop car if controller is disconnected.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

void loop() {

int tickTime = millis();

// Command loop

while(HC06.available()) {

byte buffer[commandLength];

int size = HC06.readBytes(buffer, commandLength);

if (size != commandLength) {

continue;

}

lastCommandTimestamp = tickTime;

handleCommand(buffer);

}

handleTurn();

turnSignalControllerTick(tickTime);

stopIfDisconnected(tickTime);

}Handling commands

Extract command code and parameter, then handle each command in a separate method.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

void handleCommand(byte data[]) {

byte code = data[0];

byte param = data[1];

byte terminator = data[2];

if (terminator != commandTerminator) {

return;

}

switch (code) {

case cmdHeadlights: {

bool on = param == 0x02;

setHeadlights(on);

break;

}

case cmdGear: {

setGear(param);

break;

}

case cmdTurn: {

turnWheels(param);

break;

}

case cmdDrive: {

drive(param);

break;

}

}

}2. Headlights and turn signals

Headlights

Headlights (white LEDs) can be turned on and off manually by the user using a button in the top-right corner of an iOS application.

Connect each LED to a separate digital PIN through a resistor (220Ω) as shown in the diagram above.

Declare 4 headlights and 4 turn signals pins as constants and set their mode to OUTPUT.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

const int pinHeadlightsRight1 = 22; // Remaining headlights pin numbers: 24, 26, 28

const int pinTurnSignalLeftFront = 31; // Remaining turn signals pin numbers: 33, 35, 37

void configureLightsPins() {

pinMode(pinHeadlightsRight1, OUTPUT);

pinMode(pinTurnSignalLeftFront, OUTPUT);

...

}

void setHeadlights(bool on) {

int value = on ? HIGH : LOW;

digitalWrite(pinHeadlightsRight1, value);

digitalWrite(pinHeadlightsRight2, value);

digitalWrite(pinHeadlightsLeft1, value);

digitalWrite(pinHeadlightsLeft2, value);

}Turn signals

Turn signals (red LEDs) work automatically - they blink every 0.5 seconds when the car is turning. They work in four modes: disabled, blink left, blink right, blink both sides.

Define mode as an enum and tick interval as constant.

Use turnSignalControllerSetMode() method to change the blinking mode.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

enum Modes {

idle = 0,

blinkLeft = 1,

blinkRight = 2,

blinkBoth = 3

};

const int tickInterval = 500; // milliseconds

int lastTickTimestamp = 0;

int mode = idle;

bool ledOn = false;

void turnSignalControllerSetMode(int newMode) {

if (newMode == mode) {

return;

}

mode = (Modes)newMode;

lastTickTimestamp = 0;

updateState();

}turnSignalControllerTick() method is called from the main application loop. lastTickTimestamp stores the last timestamp (number of milliseconds passed since the Arduino board began running the current program) and compares it with the current timestamp. The result is a timer with a 500ms interval.

1

2

3

4

5

6

7

void turnSignalControllerTick(int currentTimestamp) {

if (mode == idle) { return; }

if ((currentTimestamp - lastTickTimestamp) > tickInterval) {

lastTickTimestamp = currentTimestamp;

updateState();

}

}Method updateState() turns LEDs on and off depending on the current mode.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

void updateState() {

if (mode == idle) {

ledOn = false;

} else {

ledOn = !ledOn;

}

int value = ledOn ? HIGH : LOW;

switch (mode) {

case idle:

case blinkBoth:

digitalWrite(pinTurnSignalLeftFront, value);

digitalWrite(pinTurnSignalLeftRear, value);

digitalWrite(pinTurnSignalRightFront, value);

digitalWrite(pinTurnSignalRightRear, value);

break;

case blinkLeft:

digitalWrite(pinTurnSignalLeftFront, value);

digitalWrite(pinTurnSignalLeftRear, value);

digitalWrite(pinTurnSignalRightFront, LOW);

digitalWrite(pinTurnSignalRightRear, LOW);

break;

case blinkRight:

digitalWrite(pinTurnSignalLeftFront, LOW);

digitalWrite(pinTurnSignalLeftRear, LOW);

digitalWrite(pinTurnSignalRightFront, value);

digitalWrite(pinTurnSignalRightRear, value);

break;

}3. Driving

Connect DC motors to the Motor Control Shield L293D:

DC motor for driving to M3 interface.

DC motor for turning to M4 interface.

Define and configure DC the motor pins

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

const int pinMotorDrive_dir1 = 8;

const int pinMotorDrive_dir2 = 7;

const int pinMotorDriveSpeed_pwm = 10;

const int pinMotorTurn_dir1 = 12;

const int pinMotorTurn_dir2 = 13;

const int pinMotorTurnSpeed_pwm = 11;

void configureMotorPins() {

pinMode(pinMotorDrive_dir1, OUTPUT);

pinMode(pinMotorDrive_dir2, OUTPUT);

pinMode(pinMotorDriveSpeed_pwm, OUTPUT);

pinMode(pinMotorTurn_dir1, OUTPUT);

pinMode(pinMotorTurn_dir2, OUTPUT);

pinMode(pinMotorTurnSpeed_pwm, OUTPUT);

digitalWrite(pinMotorDrive_dir1, 1); // set forward direction

digitalWrite(pinMotorDrive_dir2, 0); // set forward direction

digitalWrite(pinMotorDriveSpeed_pwm, HIGH); // set to high to enable the L293 driver chip

analogWrite(pinMotorDriveSpeed_pwm, 0); // set speed to 0

digitalWrite(pinMotorTurn_dir1, 1); // set forward direction

digitalWrite(pinMotorTurn_dir2, 0); // set forward direction

digitalWrite(pinMotorTurnSpeed_pwm, HIGH); // set to high to enable the L293 driver chip

analogWrite(pinMotorTurnSpeed_pwm, 0); // set speed to 0

}Handle the drive command

Speed parameter (0-127 - drive backwards, 127 - stop, 128-255 - drive forward) must be converted into a speed (0-255) and direction. Choose the minimum speed/voltage depending on the car weight and DC motor parameters.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

void drive(byte value) {

int minSpeedValue = 100;

int maxSpeedValue = 255;

if (value < 127) { // backwards

digitalWrite(pinMotorDrive_dir1, 0);

digitalWrite(pinMotorDrive_dir2, 1);

int speedValue = minSpeedValue + (maxSpeedValue - minSpeedValue) * (127 - value) / 127;

analogWrite(pinMotorDriveSpeed_pwm, speedValue);

} else if (value > 127) { // forward

digitalWrite(pinMotorDrive_dir1, 1);

digitalWrite(pinMotorDrive_dir2, 0);

int speedValue = minSpeedValue + (maxSpeedValue - minSpeedValue) * (value - 127) / 127;

analogWrite(pinMotorDriveSpeed_pwm, speedValue);

} else { // 127 stop

digitalWrite(pinMotorDrive_dir1, 1);

digitalWrite(pinMotorDrive_dir2, 0);

analogWrite(pinMotorDriveSpeed_pwm, 0);

}

}4. Turning

Read current front wheels angle using a potentiometer

Connect potentiometer pins to the board:

First outer pin to the ground

Second outer pin to 5V

Middle pin to the Arduino analog pin number A0

1

2

3

4

5

6

const int pinPotentiometer = A0;

int readPotentiometer() {

int sensorValue = analogRead(pinPotentiometer);

return sensorValue;

}Convert the target angle

Convert target angle received from an iPhone (0-255) to integer (0-1024) in order to compare it with the potentiometer reading.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

void turnWheels(byte value) {

int minLeft = 300; // it means that the wheels are turned all the way to the left

int maxRight = 900; // wheels turned all the way to the right

int center = 600; // wheels are straight

if (value < 127) { // turn left

turnSignalControllerSetMode(1);

float factor = ((float)value)/127.0;

targetTurnValue = minLeft + factor * (center - minLeft);

} else if (value == 127) { // straight

turnSignalControllerSetMode(0);

targetTurnValue = center;

} else if (value > 127) { // turn right

turnSignalControllerSetMode(2);

float factor = ((float)value - 127.0) / 128.0;

targetTurnValue = center + 1 + factor * (maxRight - center - 1);

}

}Turn wheels

Method handleTurn() does a few things:

Reads the current wheels angle using the potentiometer. analogRead()returns integer value between 0-1024 which represents an angle.

Calculates which direction to turn the wheels to - left, right, or stop when the angle is reached.

Starts/stops turn signals.

Choose the speed/voltage depending on the DC motor parameters.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

void handleTurn() {

int sensorValue = readPotentiometer();

const int tolerance = 20;

const int speed = 130;

if (abs(sensorValue - targetTurnValue) < tolerance) {

// value reached, stop motor

analogWrite(pinMotorTurnSpeed_pwm, 0);

} else if (sensorValue > targetTurnValue) {

// turn left

digitalWrite(pinMotorTurn_dir1, 0);

digitalWrite(pinMotorTurn_dir2, 1);

analogWrite(pinMotorTurnSpeed_pwm, speed);

} else if (sensorValue < targetTurnValue) {

// turn right

digitalWrite(pinMotorTurn_dir1, 1);

digitalWrite(pinMotorTurn_dir2, 0);

analogWrite(pinMotorTurnSpeed_pwm, speed);

}

}That’s pretty much everything. I hope you enjoyed this article and you will build your toy car!

Krzysztof Pelczar

iOS Developer